Customization Capabilities

Customized promotional products often involve applying logos, brand marks, and designs onto various items using methods such as screen printing, embroidery, and laser engraving. Customization goes beyond simple logo placement — it also includes personalizing the product itself, enabling brands to create functional, impressive, and high-value items that align with their brand image and target audience. Each method involves distinct techniques that influence the final outcome, making it essential to choose the right approach for each material and design. You can rely on us for dependable, fast, and fully tailored solutions that perfectly meet your needs.

This allows brands to create practical, eye-catching, and high-perceived-value products that stay consistent with their brand identity and audience expectations.

1、Screen Printing

Screen printing is ideal for creating vibrant, eye-catching designs on fabric items such as T-shirts, tote bags, and caps.This technique can be applied to a wide range of materials and product shapes, though it’s most commonly used for textiles. Logos are transferred onto the product through a stencil and a squeegee.We offer both manual and automated screen printing, ensuring exceptional print quality and high production efficiency. Screen printing is known for its durability and long-lasting results.To this day, no digital printing technology has surpassed the quality of this traditional printing method.

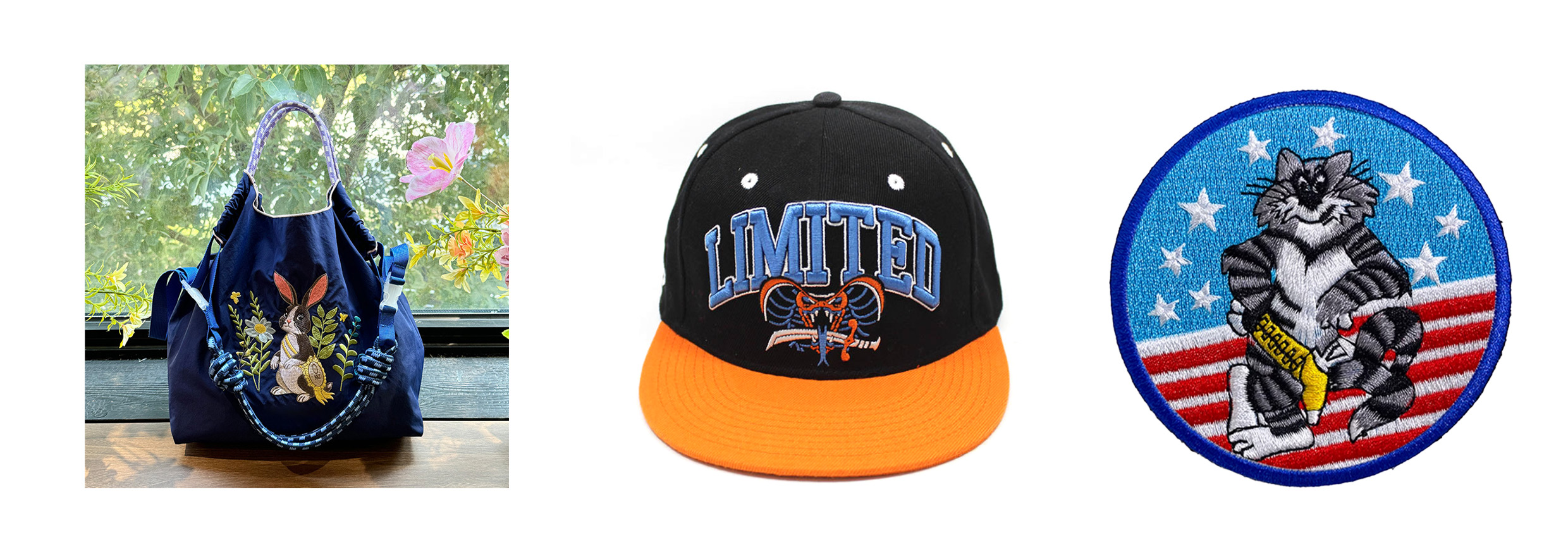

2、Embroidery

Embroidery is a popular technique that gives apparel and accessories a professional and durable appearance.Logos can be stitched onto almost any fabric item — towels, bags, caps, T-shirts, jackets, and more.Before embroidery begins, a digital embroidery file must be created. The item is then secured onto a special frame, and the machine completes the stitching automatically. The finishing touches are done by hand for a clean, refined result.

3、Laser Engraving

Laser engraving is a precise technique used on metals and other materials to create a premium, long-lasting visual effect.The laser beam etches through the surface layer of materials like metal, coated metal, wood, or plastic, revealing the base color underneath.This method produces highly detailed, high-quality, and permanent markings.

4、Heat Transfer Printing

Heat transfer printing is perfect for complex or multicolored images that require fine details.The process begins by printing the mirrored design onto transfer paper using screen printing. Then, a heat press machine transfers the image onto the product under controlled temperature, pressure, and time.Ideal for items like T-shirts, hats, tote bags, and backpacks.

5、Full-Color Digital Printing

This technique can be applied to various materials, including paper products and certain fabrics.Using advanced inkjet technology, liquid ink is directly sprayed onto the surface and instantly cured with UV light.It enables detailed designs, photo-quality images, and vibrant color gradients.Best suited for flat or slightly curved surfaces — such as mugs, power banks, and tech accessories.

6、Pad Printing

Pad printing can be used on almost any material — plastic, glass, metal, wood, leather, or ceramic.It uses a silicone pad to transfer ink from an engraved plate (the cliché) onto the product surface.Perfect for small promotional items such as pens, bottle openers, lighters, and keychains.

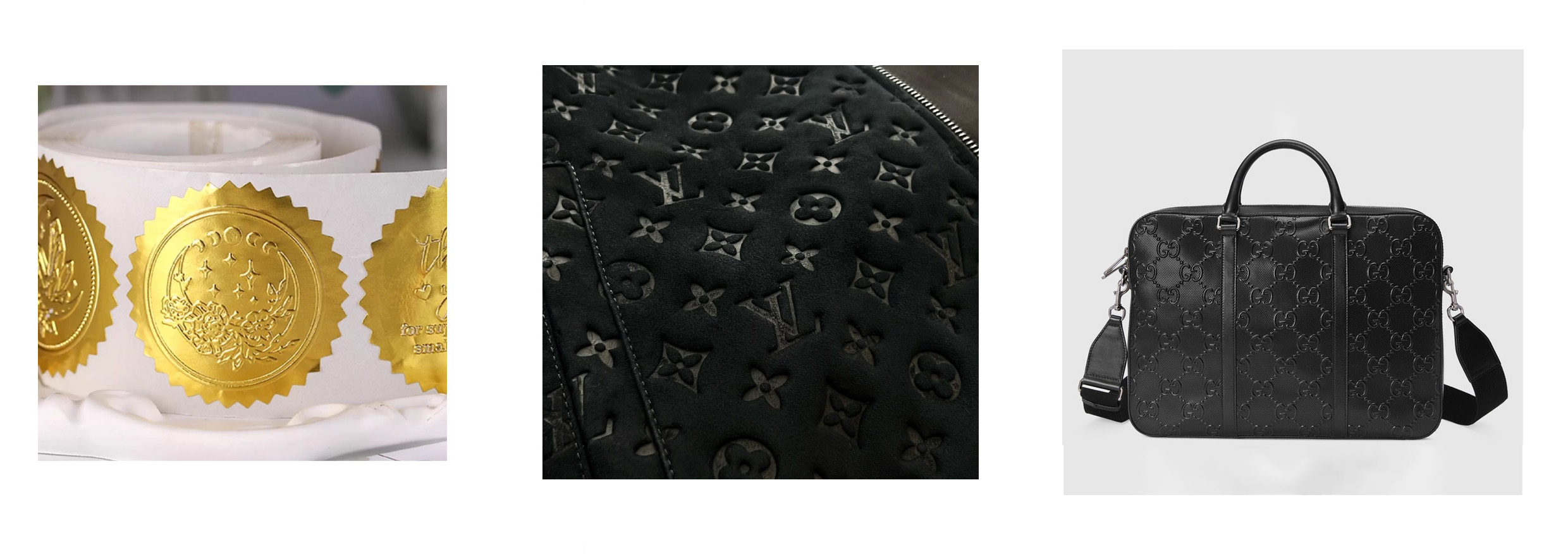

7、Embossing / Debossing

Embossing and debossing are used for branding on materials like leather, PU, paper, or textiles.There are two main types: blind embossing and foil embossing.Blind embossing creates a subtle raised or recessed texture, while foil embossing applies metallic foils — typically gold or silver — for a luxurious finish.

8、Epoxy Doming

Epoxy doming involves covering digitally printed stickers with a layer of clear epoxy resin to create a 3D look.It enhances color vibrancy and protects the surface from scratches and damage.Ideal for products that cannot be printed on directly.

9、Sublimation Printing

Sublimation printing allows for full-color, long-lasting prints with exceptional vibrancy.However, it is limited to polyester fabrics or coated surfaces, ideally white for best results.It delivers maximum color accuracy and gradient smoothness.

10、Sandblasting

Sandblasting is used to create brand markings on materials like ceramics, glass, and metal.Fine sand is blasted through a stencil to etch a design onto the surface, producing a clean, frosted look — ideal for mugs, glassware, and metal bottles.

Custom Production Focus

To make your promotional products, uniforms, and personalized textiles stand out, we focus on:

- ① Material sourcing

- ② Product and service research

- ③ Design and color coordination

- ④ Budget management

- ⑤ Quality control in production

- ⑥ Production tracking and coordination

- ⑦ Supplier sourcing and evaluation

With an extensive range of materials and advanced printing techniques, we deliver high-quality, fully customized promotional gifts. From logo engraving and screen printing to full-color transfers, every item is crafted with precision to showcase your brand perfectly. Our strong production capacity and flexible customization options make us a trusted partner for clients worldwide — helping them achieve their marketing goals with ease. Entrust your project to us, and we’ll take care of everything to create promotional items that truly reflect your brand image!