The global insulated drinkware and tumbler market has been expanding rapidly as both consumers and brands prioritize sustainability, personalization, and reusable product solutions. Industry projections and segment reports indicate that drinkware is gaining traction with consumers globally, with insulated drinkware projected to reach USD 7.26 billion by 2032, driven by rising demand for on-the-go and personalized beverage solutions.

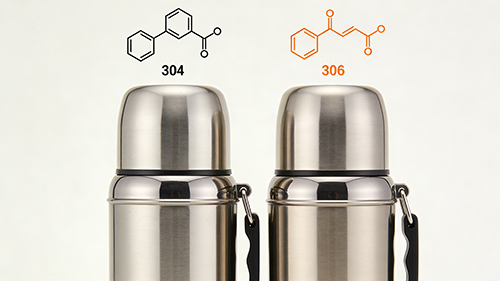

When selecting materials for custom insulated tumblers, understanding stainless steel grades is essential for durability, thermal performance, and long‑term consumer satisfaction. Two commonly referenced food‑grade alloys are 304 stainless steel and 306 stainless steel — both used in premium drinkware manufacturing but with distinct performance traits. This guide outlines key differences and helps corporate buyers make informed material selections for custom promotional tumblers.

1. Materials FAQ: Choosing the Right Stainless Steel and Eco-Friendly Options

Q: Key Differences Between 304 and 306 Stainless Steel Tumblers

| Feature | 304 Stainless Steel | 306 Stainless Steel |

| Alloy Composition | Contains ~18% chromium, ~8% nickel | Similar chromium but higher nickel content than 304 |

| Corrosion Resistance | Excellent for everyday use | Enhanced corrosion resistance, ideal for more demanding environments |

| Oxidation Resistance | Strong oxidation protection | Slightly better performance in chemical or acidic exposure |

| Hardness & Wear Resistance | Good hardness | Higher durability under stress |

| Cost | More affordable | Higher material cost due to increased alloy content |

| Typical Applications | Everyday drinkware & tumblers | Premium products, industrial or specialty use |

| Lifespan | Long‑lasting for most use cases | Extended lifespan in aggressive conditions |

Q: Are 304 and 306 stainless steel tumblers priced the same?

A: 306 stainless steel tumblers are typically more expensive than 304 due to higher nickel content and improved corrosion resistance, which increases raw material and manufacturing costs.Q: Which is better for daily use, 304 or 306 stainless steel tumblers?

A: For everyday corporate or consumer use, 304 stainless steel tumblers are sufficient — they offer robust corrosion resistance, durability, and cost‑effectiveness for hot and cold beverages.Q: What occasions are 306 stainless steel tumblers best suited for?

A: 306 stainless steel tumblers excel in harsher environments like high humidity, coastal climates, or outdoor use, and are ideal for premium promotional gifts emphasizing durability and long‑term performance.Q: How does the price difference affect corporate customization costs?

A: If your organization prioritizes cost control or large bulk orders, 304 is practical and value‑oriented. For high‑end branding or luxury promotional campaigns, 306 may justify its higher unit cost.Q: Can 304 stainless steel tumblers rust?

A: 304 stainless steel is highly corrosion‑resistant and food‑safe, but prolonged exposure to very humid or highly chloride‑rich environments can cause minor surface corrosion.2.Design FAQ: Shapes, Sizes, and Lid Types for Corporate Use

Q: What factors affect the cost of custom tumblers?

A: Material quality (304 vs 306 stainless steel), lid type, capacity, and insulation performance directly impact cost-per-unit for corporate campaigns.Q: How do I choose tumbler capacity for employees vs clients?

A: Employee gifts: 12–16oz, suitable for daily use. Client gifts: 20–32oz, offering higher perceived value and extended brand exposure.

Q: How to choose tumbler size for different scenarios?

Daily commute: 350–500 mlLong outings: 600 ml–1 L

Fitness or sports: 500–750 ml

Home or office: 500–800 ml

Children: ~350 ml

Q: What types of custom tumbler designs are available for corporate branding?

A: Options include stainless steel vacuum-insulated, double-wall glass, plastic BPA-free, and hybrid designs. Each design suits different use cases such as employee gifts, client giveaways, or trade show promotions.

Q: What design shapes work best for corporate giveaways?

A: Standard cylindrical tumblers are versatile. Curved, tapered, or custom silhouettes (like logo shapes) create higher brand impact.

Q: Can tumblers be customized with full-color graphics?

A: Yes, heat transfer or UV printing supports full-color, complex graphics, including logos and slogans for marketing campaigns.Q: Can tumblers be combined with other promotional items?

A: Yes, they can be included in corporate gift sets with tote bags, notebooks, or reusable straws for high-impact promotional kits.Q: Are there tumblers suitable for seasonal or themed events?

A: Yes, limited edition designs for holidays, anniversaries, or campaigns with custom colors or graphics enhance brand memorability.Q: Can corporate tumblers include smart features?

A: Some designs integrate temperature sensors, digital displays, or leak-proof locking mechanisms, appealing to tech-savvy employees or clients.

Q: How do I ensure logo visibility on different tumbler designs?

A: Larger flat surfaces allow full-color printing, while curved shapes may require laser engraving for clear brand visibility.

Q: How do I select the right lid type for corporate tumblers?

A: Options include sliding, flip-top, straw, or screw lids. Choose based on usage scenario: flip-top for office, straw lids for outdoor or fitness events.3.Customization FAQ: Logo Printing, Engraving, and Packaging Options

Q: What printing methods are recommended for corporate logos?

A: Screen printing, heat transfer, and laser engraving. Screen printing is cost-effective for bulk, heat transfer allows full-color designs, laser engraving creates a premium finish.Q: Can tumblers be packaged for premium presentation?

A: Options include individual gift boxes, eco-friendly sleeves, or branded inserts, boosting perceived value and brand recall.Q: Can I request samples before mass production?

A: Yes. Customized samples can be provided for verification before mass production to ensure consistency in brand image.Q: How long does it take to produce custom tumblers?

A: Typical lead time is 2–6 weeks, depending on insulation type, bulk quantity, and design complexity.4.Thermal Performance FAQ: Hot & Cold Retention and Usage Tips

Q: How long do insulated tumblers maintain hot or cold beverages?

A: Double-wall vacuum tumblers retain hot drinks 6–12 hours and cold drinks 12–24 hours, depending on material quality and lid sealing.Q: What factors affect the cost of custom tumblers?

A: Material quality (304 vs 306 stainless steel), lid type, capacity, and insulation performance directly impact cost-per-unit for corporate campaigns.Q: How long does it take to produce custom tumblers?

A: Typical lead time is 2–6 weeks, depending on insulation type, bulk quantity, and design complexity.

Q: How do I choose tumbler capacity for employees vs clients?

A: Employee gifts: 12–16oz, suitable for daily use. Client gifts: 20–32oz, offering higher perceived value and extended brand exposure.

|

|

|

|

|

|