In today's increasingly fragmented brand communication landscape, enterprises need a promotion method with controllable costs, high exposure frequency, and flexible usage. Compared with one-time advertising, custom stickers are gradually becoming a common choice in corporate brand promotion, product packaging, and event marketing.

What is a Custom Sticker? A custom sticker refers to an exclusive sticker designed and produced according to the enterprise's brand needs, usually containing the enterprise's LOGO, patterns, brand slogans, or functional information. Small in size yet reusable; low in cost yet highly visible. Whether attached to product packaging, logistics boxes, or used as event gifts, a well-designed sticker can keep the brand visible in daily scenarios.

What Factors Should Enterprises Consider When Customizing Stickers?

1. Design Content

Brand Logo and Trademark

Enterprises often print their brand LOGO or trademark on custom stickers, which is crucial for enhancing brand awareness and recognition. Trademark-protected patterns: such as classic product patterns or unique patterns of other brands, ensuring these design elements are protected and displayed.

Product Name and Description

Stickers can be used to mark product names, especially on packaging and labels, to help consumers identify products. Ingredients or usage instructions: especially for food, cosmetics, and other products, stickers can be used to display ingredients, usage methods, production dates, and other information.

Creative Patterns and Illustrations

Unique illustrations or artistic patterns: such as cartoon characters, works of art, decorative patterns, etc., which can make stickers more creative and attractive. Graphic design: can be simple geometric shapes, line patterns, or complex illustrations, these designs make stickers more personalized.

Text and Slogans

Advertising slogans: Enterprises can print their promotional slogans or advertising phrases on stickers to attract customers' attention and convey brand value. Inspirational quotes or humorous texts: suitable for social media activities, brand interactions, etc., attracting customers through interesting or thought-provoking texts.

Contact Information

Phone numbers, email addresses, website URLs: Enterprises often add their contact information when customizing stickers to facilitate customers to contact or obtain more brand information. Social media accounts: especially in the social media era, stickers can print brand social media accounts (such as Instagram, Facebook, Weibo, etc.) to help brands increase exposure.

Personalized Design

Names or personalized texts: For personalized products, stickers can print customers' names, personalized blessings, or other customized content. Birthday and holiday blessings: such as holiday-specific stickers, designed with special blessings or patterns for specific holidays (such as Christmas, Spring Festival, Valentine's Day, etc.) to enhance the holiday atmosphere.

2. Size and Shape

Stickers can be cut arbitrarily according to design needs. Common shapes include circles, squares, rectangles, hearts, stars, etc. Custom die-cut stickers (such as making stickers according to the shape of LOGO or patterns) are also available. Sizes can usually be customized, including mini stickers suitable for small items and larger sizes suitable for large-area displays.

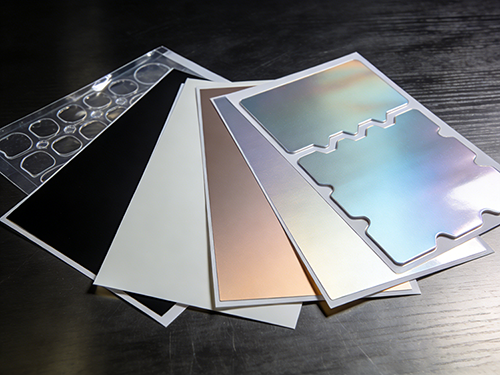

3. Custom Sticker Materials and Effects

● Paper Stickers

Features: Usually used for indoor applications, such as packaging, cards, promotional activities, etc. Advantages: Low cost, suitable for one-time use or short-term display. Disadvantages: Not waterproof, easy to wear, narrow scope of application.

● Custom Vinyl Stickers

What are vinyl stickers? Vinyl stickers are stickers made of vinyl material, commonly used in various scenarios such as brand marketing, advertising, and personal customization. Vinyl is a durable and flexible plastic material widely used in the production of stickers and labels. Features: Due to its excellent durability and waterproofness, it has become the preferred material for many enterprises and individuals to choose custom stickers. Advantages: High durability, waterproof, scratch-resistant and wear-resistant, suitable for various surfaces. Disadvantages: Relatively high price, difficult to remove. For more details on vinyl sticker materials, you can refer to SignWarehouse's Vinyl Sticker Guide.

● Custom Magnetic Stickers

Features: With magnetism on the back, can be directly attached to iron surfaces. Advantages: Reusable, no damage to surfaces. Disadvantages: Limited to being attached only to metal surfaces.

● Clear PVC Stickers

Clear stickers are made of polyvinyl chloride (PVC), with waterproof, oil-resistant, and wear-resistant properties. The back is transparent, and only the pattern or text part has color. Features: Transparent material, only the pattern or text part has color, and the background is transparent. Advantages: Suitable for glass, windows and other surfaces, does not affect the original background. Disadvantages: The printed color may appear lighter due to the influence of the background. For professional insights on clear sticker applications, check StickerPrinting.co.uk's Clear Stickers Guide.

● Eco-friendly Stickers

Features: Made of degradable materials or printed with eco-friendly inks, meeting environmental standards. Advantages: In line with environmental protection concepts, suitable for environmentally friendly brands. Disadvantages: Usually slightly higher price than ordinary stickers. For the latest trends in eco-friendly packaging materials, refer to EPA's Sustainable Materials Management report.

● Custom Glitter Stickers

A type of sticker with a sparkling effect, usually made of materials containing sequins or glossy particles. It presents a sparkling effect under light, giving a vibrant visual impact. Advantages: Strong visual appeal, enhanced brand exposure, suitable for various occasions, good durability. Disadvantages: High price, not suitable for all surfaces.

● Custom Holographic Stickers

What are holographic stickers? Holographic stickers are made of special holographic materials, which can present sparkling rainbow light effects at different angles and under different lights, bringing a strong visual impact. Advantages: High visual appeal, personalization and uniqueness, enhancing brand value. Disadvantages: High price, not suitable for all surfaces, easy to be damaged.

● Custom Prismatic Stickers

Prismatic stickers refer to custom prismatic effect stickers, usually with colorful luster and reflection effects, which can show different colors and patterns at different angles. The surface of the sticker presents a colorful and shimmering effect, like a spectrum. Advantages: Eye-catching visual effect, bright colors, able to attract attention and increase decoration. Disadvantages: High production cost, easy to scratch or wear, which may affect the durability of the visual effect.

● Custom Embossed Stickers

Embossed stickers are custom stickers with a three-dimensional effect. The surface is raised or concave through special processes to create a sense of depth in touch and vision. Advantages: Unique touch, three-dimensional visual effect, able to enhance the texture and attractiveness of the sticker. Disadvantages: Complex production process and high cost, which may lead to thick stickers that are difficult to fit on uneven surfaces.

● Foil Stickers (Gold & Silver)

Foil stickers are made using metal foil printing technology, usually with a shiny metallic luster, increasing the luxury and high-end sense of the sticker. Advantages: Strong high-end visual effect, suitable for gift packaging, brand logos and other occasions that need to highlight quality. Disadvantages: Easy to scratch or fade, and high production cost.

● Custom Glow in the Dark Stickers

Custom glow in the dark stickers are stickers that can glow in the dark, usually made of special fluorescent materials, so that they can still emit light after the light source disappears. Advantages: Glow at night, increase fun and visibility, suitable for decoration, guidance or identification. Disadvantages: The luminous effect is usually limited, and it needs to be regularly exposed to light to maintain the best effect.

4. Classification by Process: Sticker Printing

Screen Printed Stickers

Features: Produced through screen printing process, suitable for mass production. Advantages: Full color, suitable for large-scale production. Disadvantages: Limited handling of complex designs and gradient colors. Applications: Mass-produced labels, commercial promotional stickers. For technical details on screen printing, refer to SGIA's Screen Printing Guide.

Digital Printed Stickers

Features: Adopt digital printing technology, suitable for complex patterns and small-batch production. Advantages: Fine, bright colors, suitable for complex designs. Disadvantages: Higher cost compared to screen printing. Applications: Personalized designs, custom stickers, limited edition stickers.

Heat Transfer Stickers

Features: Transfer patterns to the material surface through heat transfer technology. Advantages: Can achieve complex and detailed designs, suitable for textiles and clothing. Disadvantages: Require special equipment, limited scope of application. Applications: Printing on T-shirts, sportswear, fabrics.

5. Basic Process of Custom Stickers for Enterprises: How to Make a Custom Sticker

The process of making custom stickers is relatively simple. Following the steps below can ensure that the stickers meet the enterprise's needs and are successfully produced.

1. Confirm Purpose and Size: Determine the final purpose of the sticker (such as promotion, packaging, identification, etc.), and select the appropriate size and shape according to needs to ensure it fits the usage scenario.

2. Provide Design Files or Seek Supplier Design Assistance: Enterprises can provide their own design files (such as AI, PDF formats, etc.), or choose to cooperate with suppliers to help design stickers, ensuring the design conforms to the brand image and needs.

3. Select Materials and Processes: According to the sticker's purpose, select suitable materials (such as paper, PVC, vinyl, etc.) and printing processes (such as screen printing, digital printing, embossing, foil stamping, etc.) to meet durability, visual effect and budget requirements.

4. Sample Confirmation: After providing the design, the supplier will make samples. The enterprise confirms whether the quality, color, size, etc. of the samples meet the requirements, and enters the mass production stage after ensuring no problems.

5. Mass Production and Delivery: After the sample is confirmed to be correct, formal mass production is carried out, and production and delivery are completed within the agreed time to ensure timely delivery to the enterprise for use.

Through these five steps, enterprises can easily customize stickers that meet their own needs, while ensuring efficient production and delivery.

FAQ

Q: How to Choose Custom Sticker Sizes?

A: Choosing the size of the sticker mainly depends on the purpose and application scenario. For example: For small items (such as mobile phones, notebooks): It is recommended to choose small-sized stickers (such as 2-4 inches). For promotion or display: Larger sizes are more attractive, and you can choose 5-8 inches or larger. Specific designs: If the design has details or complex patterns, the size can be adjusted according to the actual needs of the design to ensure the pattern is clearly visible.

Q: Why Are Custom Stickers a Cost-Effective Choice for Enterprises?

A: As a corporate marketing and brand promotion tool, custom stickers have the following advantages: Low cost and high exposure: Compared with traditional advertising forms (such as TV, radio advertisements, etc.), custom stickers have lower production costs, and their communication effect is extensive, which can be continuously displayed in daily life, bringing long-term brand exposure. High flexibility: Stickers can adapt to different marketing needs, from small-scale activities to large-scale promotion, the quantity and design can be flexibly adjusted to ensure efficient use of the budget. Easy to distribute: Stickers are small in size and light in weight, easy to mass produce and distribute, and can reach potential customers through various channels such as mail, on-site activities, and gifts. According to a Statista report on advertising cost-effectiveness, customized promotional materials like stickers have a higher ROI than traditional media ads.

Q: What Is the Role of Custom Stickers?

A: Custom stickers have a variety of roles, mainly including: Brand promotion: Enterprises can spread brand logos, slogans or event information through custom stickers to increase brand exposure. Personalized decoration: Individuals and groups can express their personality, hobbies or unique styles through custom stickers, decorating mobile phones, notebooks, luggage and other items. Information transmission: Custom stickers can be used to convey important information, warning signs or event guidelines, widely used in commercial, educational, health and other fields. Gifts and souvenirs: Custom stickers can also be distributed as gifts, souvenirs or promotional items to enhance the commemorative value of special events or activities.

Q: What Are the Uses of Stickers?

A: Stickers have a wide range of uses, including but not limited to: Decorations: Used for personalized decoration of items, such as water bottles, phone cases, cars, walls, etc. Promotional tools: As advertising or brand promotion tools, widely used in stores, events or social media promotion. Creative art: Used for DIY crafts, art creation or design projects. Educational tools: Used in educational scenarios for rewards, learning aids or display projects. Reminders and marks: Used in workplaces or families to mark, remind or classify items.

Q: How to Remove Sticker Residue?

A: There are many ways to remove sticker residue. Common solutions include: Using warm water and soap: Soak the sticker residue with warm water and soap, wait a few minutes, then wipe with a cloth or sponge. Using alcohol or nail polish remover: Dip a cotton ball in alcohol or nail polish remover and wipe the residue, which can effectively decompose the adhesive. Using an eraser: For light residues, you can try to gently erase with an eraser. Special cleaners: There are also special cleaners on the market for removing sticky substances, which can be used according to the instructions. Using a hair dryer: Heat the sticker with a hair dryer to soften the glue, then gently peel it off with a scraper or nail.

Summary

Custom stickers are cost-effective, flexible brand promotion tools. This guide covers design, materials, processes, production flow and FAQs, helping enterprises leverage custom stickers to enhance brand exposure. Suitable for businesses seeking low-cost, high-frequency marketing solutions.